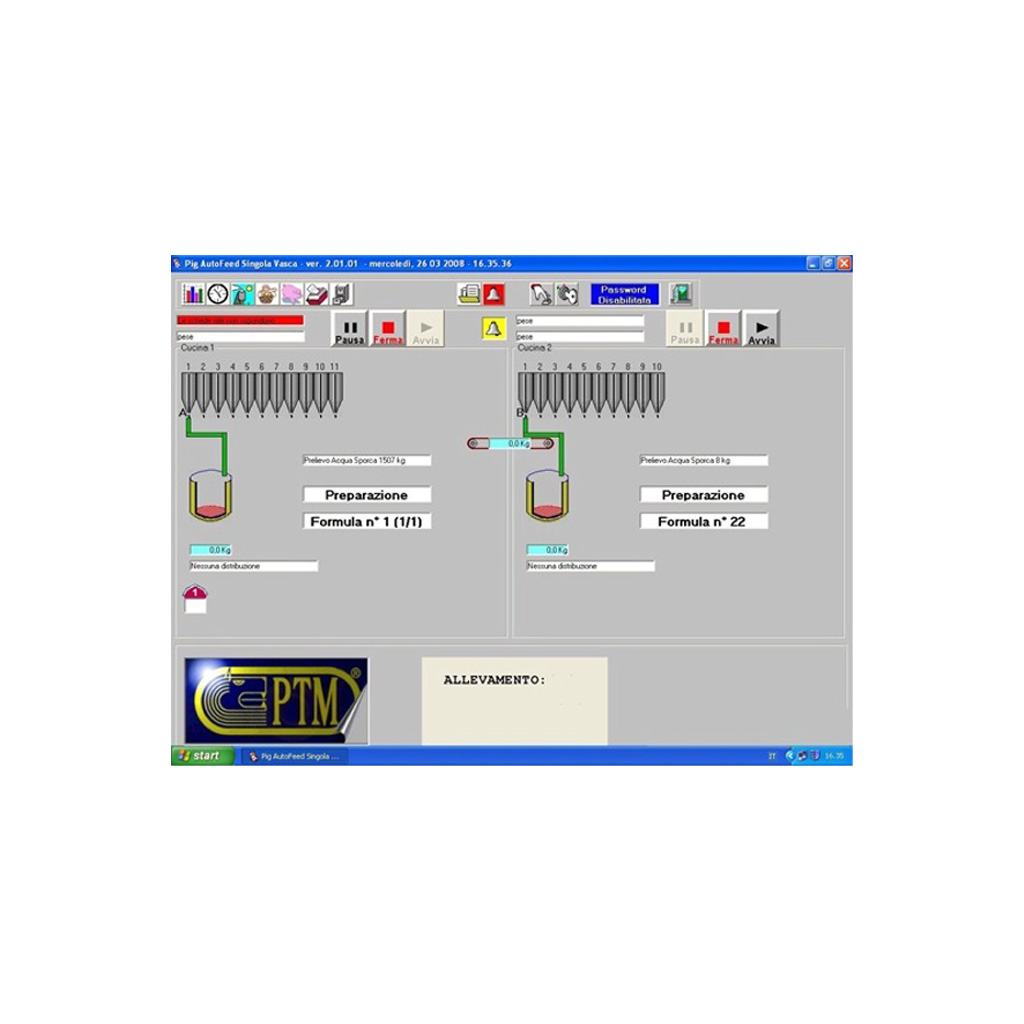

- Management of 10 lines on the kitchen “1” and 10 on the kitchen “2”

- Management of 999 valves on the kitchen “1” and 999 on the kitchen “2”

- Possibility to manage the automatic preparation of the pork-feed as previously scheduled

- Possibility to distribute the pork-feed in the boxes with reduction of relevant flux with the Bypass method

- Possibility to distribute the feed in the boxes through a pump controlled by an inverter at 4 speeds

- Unlimited feeding times

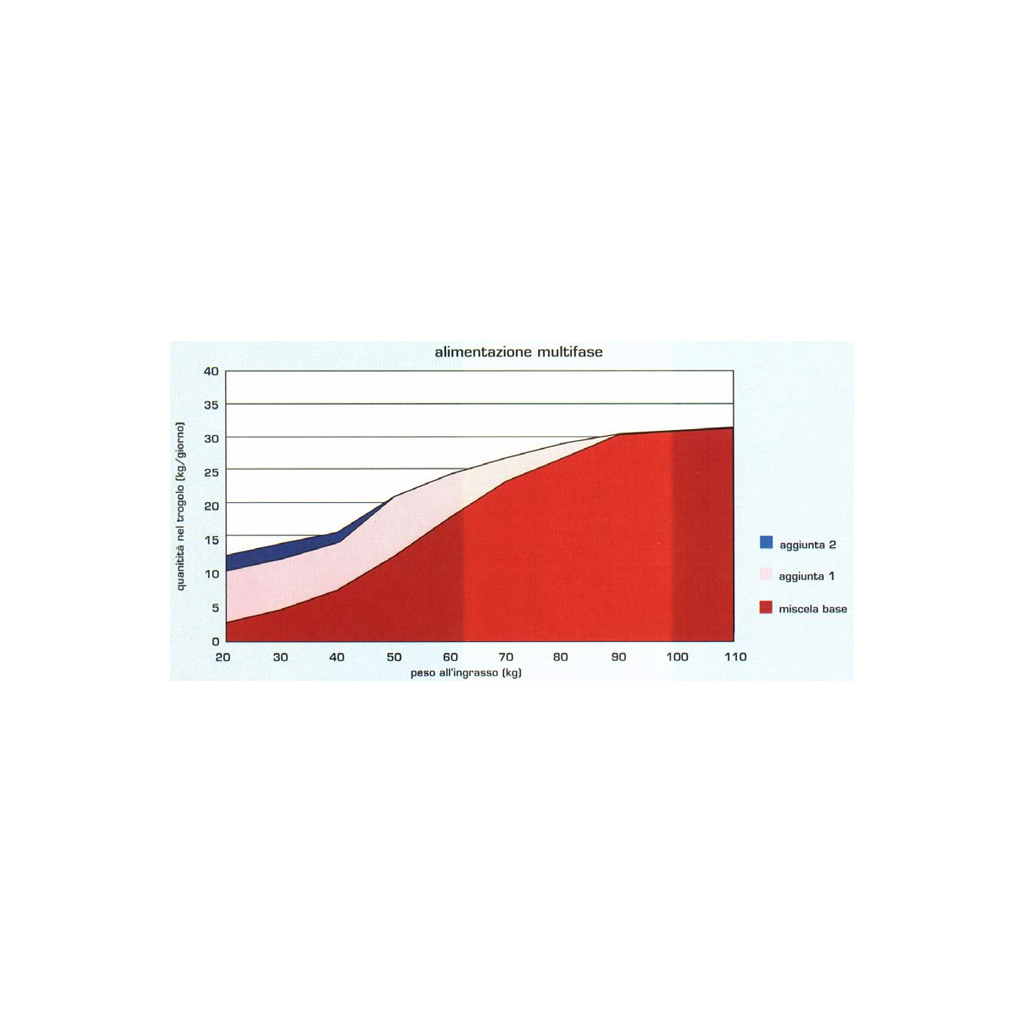

- 40 incremental curves that can be programmed either at set steps or daily. Curve visual diagram.

- 20 formulas for basin “1” and 20 formulas for basin “2”

- Different programmable mixing times for each formula

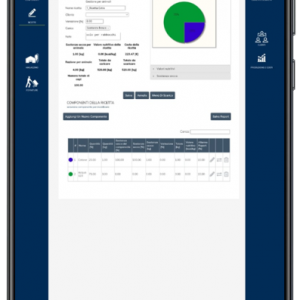

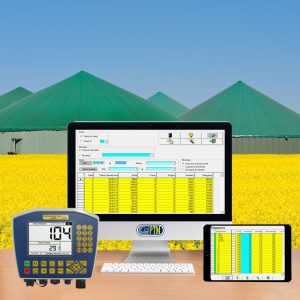

Pig Autofeed

Software utilised in the pork-breeding with the purpose to transmit the data from scale PIG 200 to the PC and vice versa through serial

The “Pig – Autofeed” program has been thought, projected and developed by PTM s.r.l. with the aim to facilitate the pork-breeders in their everyday work. This software is able to manage one or two tanks (named also “Kitchens”) which can be prepared and/or managed contemporaneously; furthermore, it manages the mixing time of pork-feed during and after the preparation and before being put in the basin for the preparation of the feed.

It co-ordinates the automatic washing of the mash piping system and it gives the chance to check the warehouse with reference to the components contained into the silos with the equipment of one alarm for the minimum. Thanks to this ingenious software it is possible to manage the animals, staying in the boxes, with all information concerning them and the dried feed consumed. There’s also the control of the NOT dosage of the feed in the box with the opportunity to manually exclude the valve that does not work in order to stop the distribution.

To guarantee the utmost safety the “Pig – Autofeed” has been programmed to maintain the preparation cycle even if the PC is irregularly switched off or if “Pig – Autofeed” is not active.