- Programming of up to 99 cards;

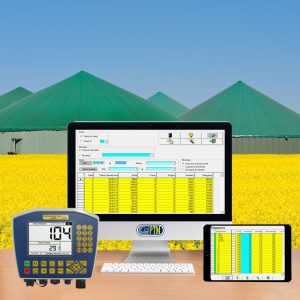

- Data transfer to the weighing computer through USB key or Memory Card;

- Use of more cards at the same time;

- Management of alarm percentages for loading and unloading operations;

- When working with USB key, it is possible to activate the function of data backup, in order to avoid losing information in case the USB key is broken or damaged;

- Compatible with Windows XP, Windows Vista and Windows 7, Windows 8.1 and Windows 10;

- Data export to Excel or Text file;

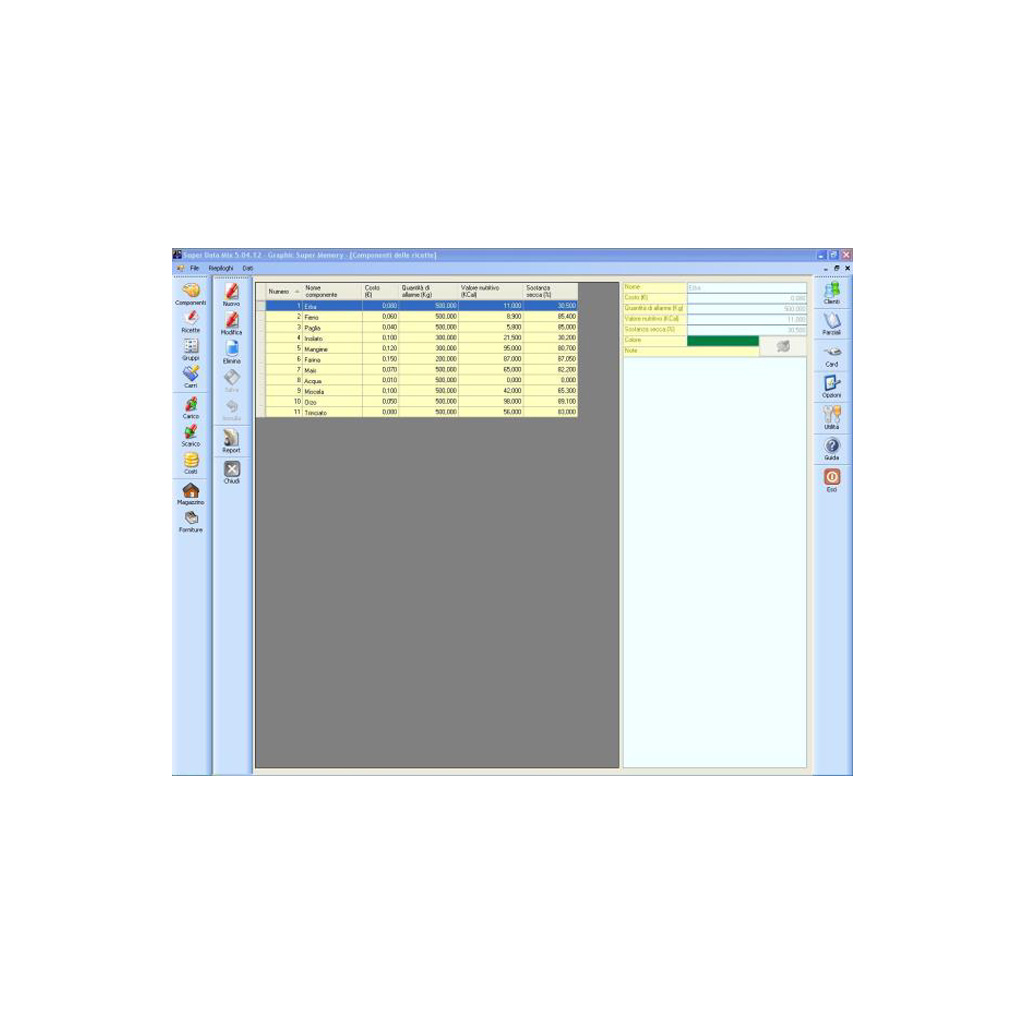

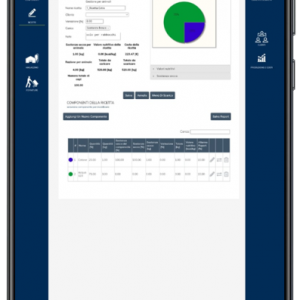

- Simple programming of recipes with settable name, up to 150 different recipes;

- Possibility to programme up to 30 components per recipe;

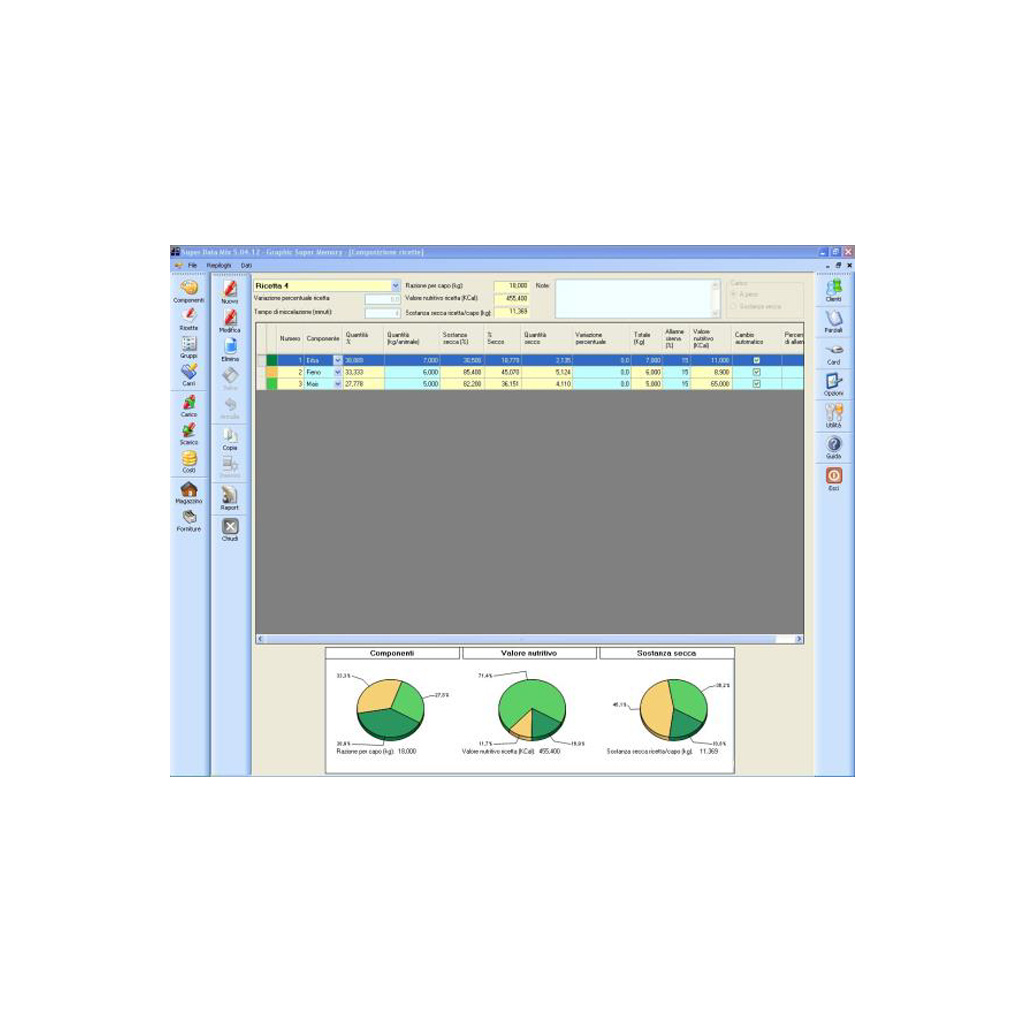

- Possibility to modify the quantity to be loaded by varying the quantity to load of each single component or of the whole recipe according to a percentage;

- Graphic representation of the distribution percentage of each single component during recipe programming;

- Management of the percentage of dried substance for each component, with its nutritive value and cost (pro Kg);

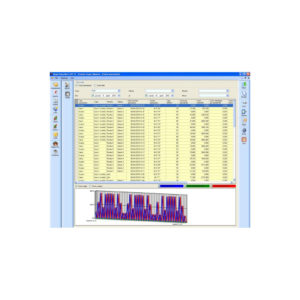

- Processing of recipe costs;

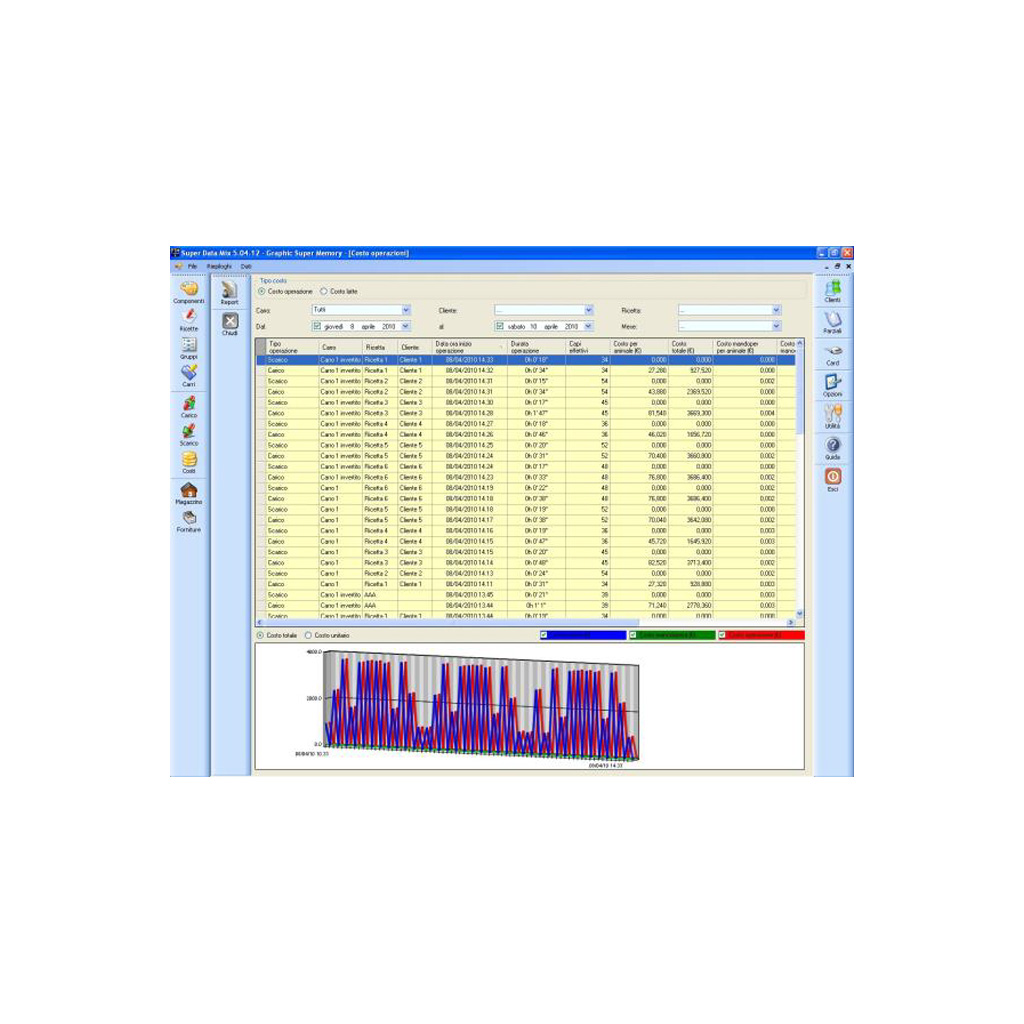

- Processing of the costs of each single operation;

- Management of labour cost;

- Management of milk price;

- Calculation of recipe proceeds and benefits;

- Graphic representation of cost trend;

- Management of a customer database;

- Possibility to register the deliveries with quantity and arrival date of the material;

- Management of a common stock and of the single stocks of the different customers, each with its alarm quantity;

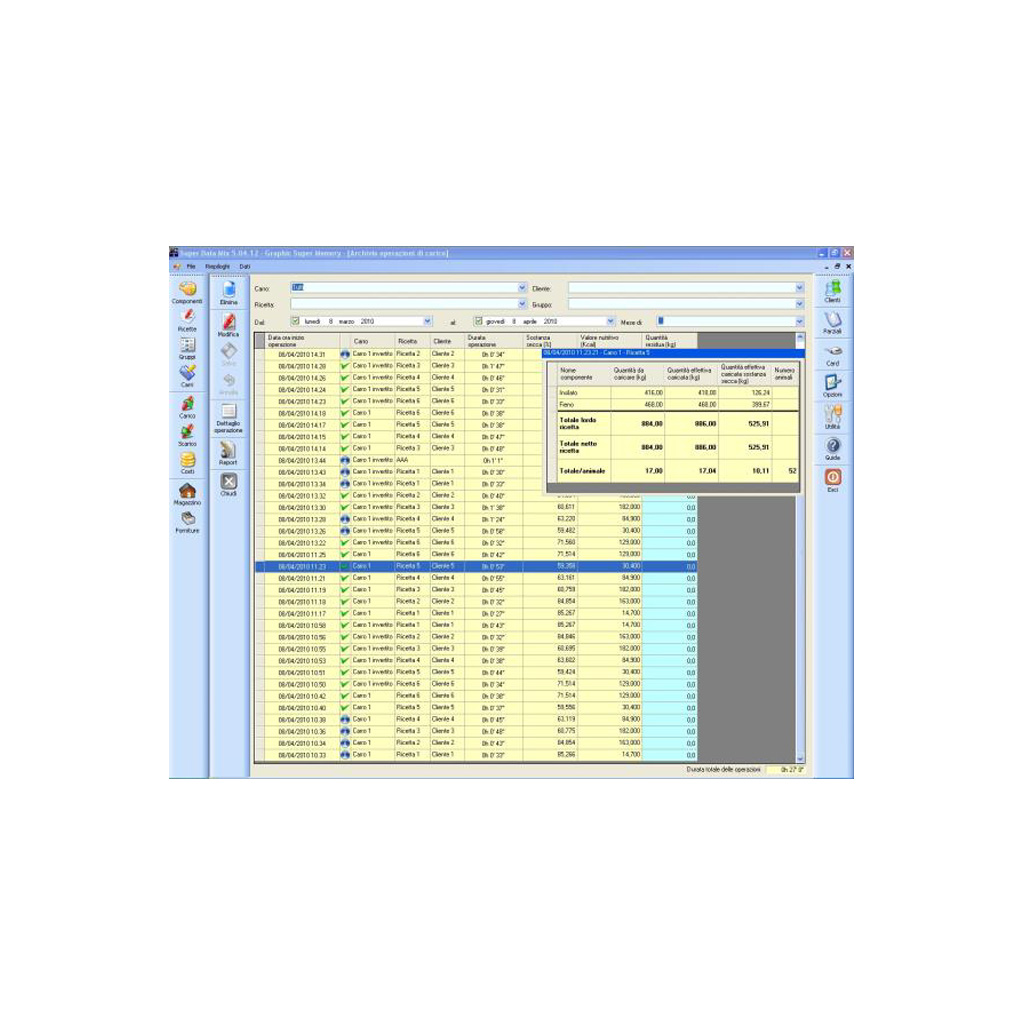

- Management of a loading archive, with possibility of searching a specific operation and displaying the details of this operation;

- Possibility to print reports for one or more operations in the loading archive; it is possible to print:

- Complete report;

- Minimum report;

- Consumption report;

- Operation list;

- Report on working time of each operation;

- List of the loaded recipe components;

- List of the loaded recipe components with corresponding values of dried substance

All these reports can be exported to Excel or Text file.

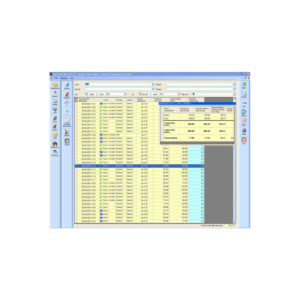

- Management of an unloading archive, with possibility of searching a specific operation and registering the amount of produced milk;

- Possibility to print reports for one or more operations in the unloading archive; it is possible to print:

- Complete report;

- Minimum report;

- Operation list;

- Report on working time of each operation;

- Report on milk production

All these reports can be exported to Excel or Text file.

- Display of partial amounts to load for each wagon;

- Possibility to send the database to the PTM technical department to find a solution to the problems;

- Possibility to replace, compress and make a backup copy of the database;

- Possibility to ask for a wireless device to transfer data from the PC to the weighing computer (through ZigBee technology)